How to choose between ODM and OEM for your next product?

Introduction

As an entrepreneur or product developer, you want a process that’s efficient, cost-effective, and aligned with your vision. OEM and ODM are two popular models in the manufacturing world, each offering unique benefits depending on your needs. In this blog, we’ll break it down simply to help you choose wisely, from real-world insights and examples.

What is OEM?

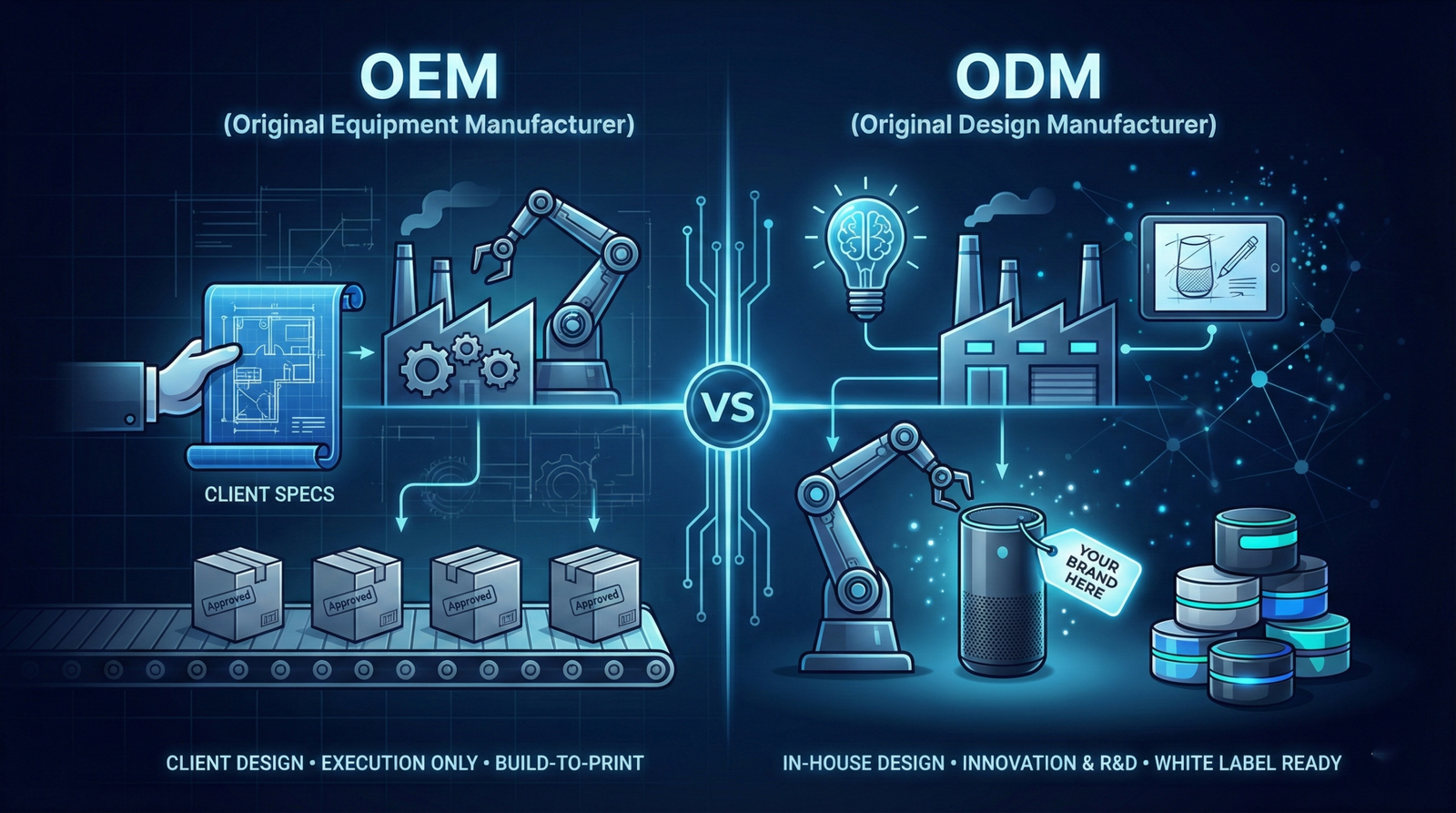

In the Original Equipment Manufacturer (OEM) model, you do the market research, the R&D, the engineering, and the design work. You create the blueprints and technical specifications. Then, you hand those specs over to a manufacturer who has the machinery and manpower to build it exactly to your standards. The OEM acts as your production partner, using its expertise in assembly, materials, and quality control to turn your ideas into tangible items. You retain full control over the intellectual property, branding, and any custom features.

Example

Nike uses an OEM approach to make shoes by assigning factories like Yue Yuen, Pou Chen in Vietnam and China. Here, Nike designs, but production is fully outsourced.

Similarly, Apple also uses an OEM approach to manufacture iPhones from Foxconn (Hon Hai Technology Group) in China, which are originally designed in Apple’s headquarters in California, USA.

What is ODM?

In Original Design Manufacturer (ODM) model, they have already researched, designed, and developed a product. They have a catalog of white-label goods ready to go. You simply select a product from their catalog, make minor adjustments (like colors or packaging), and paste your logo on it. The ODM provides ready-made designs with existing templates, and handles everything from prototyping to final assembly. You get to tweak elements like colors or logos, but the foundational design is theirs.

Example

Redmi, Vivo, and Oppo manufacture many budget and mid-range phone models (Rs. 15000-30000) using ODM partners like Wingtech, Huaqin and just make little adjustments like software, logos, color patterns for fast design and production.

Pros and Cons of Both

Choosing between OEM and ODM isn’t black and white, but it’s about what fits your goals, budget, and timeline. Let’s compare the pros and cons of them both.

OEM Pros:

- Full control: You own the design, protecting your IP and allowing endless customization.

- Quality Control: You set the standards and materials used.

- Differentiation: Your product won’t look like your competitor’s product.

OEM Cons:

- Higher costs: Developing your own design can be expensive and time-consuming.

- More responsibility: You handle all R&D, testing, and any design flaws.

- Slow to Market: Designing from scratch takes months or years.

ODM Pros:

- Speed to market: With Pre-existing designs, you can launch faster without spending time on R&D.

- Cost savings: You don’t need to hire engineers or designers for R&D because the factory does it for you.

- Lower MOQs: Since the factory is already making these, you can buy smaller batches.

ODM Cons:

- Less uniqueness: Products might resemble competitors if based on similar templates.

- IP risks: You don’t fully own the design, which could limit future modifications.

- Limited Customization: You are usually stuck with their materials and specs.

So ultimately, when deciding between OEM and ODM manufacturing, the right choice depends on your goals, resources, and timeline.

The choice between OEM and ODM comes down to your strengths and priorities. Do you need total creative control, or do you need a quicker, more collaborative approach? Evaluate your budget, timeline, and market demands thoughtfully or even consult a manufacturing expert for personalized advice.